Cost savings

Design in line with the needs of components and the correct selection of materials reduce the component costs

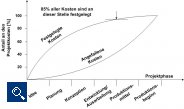

The component costs are fixed to a large extent during the conceptual design and modeling phases. The costs of manufacturing, tool design and installation are mainly determined in advance by means of the decisions made in the product development process. Therefore the multiple areas with potential should already be used to reduce costs to the optimum extent in the development phase.

Reduce cost by means of ideal component design

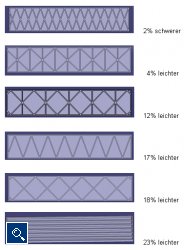

- Reduction of the wall thickness and optimization of the wall thickness distribution (e.g. increasing the strength by means of appropriate ribbing, reduction of the cycle time during the injection moulding)

- Selection of the most economic assembly technology and saving on assembly steps (snap fits, two shot moulds etc.)

- Selection of the right building structure: Differentiated design (several tools, expensive materials just for small component areas) or integrated design (reduction of the large number of parts by means of functional integration)

- Tool structure with reduced complexity (as few sliders as possible etc.)

- Only set the tolerance requirements at as high a level as necessary (reduction of tool costs, reduction of the expenditure during the quality control)

- Low warpage design

Reduce costs by means of the right material selection

- Reduction of the material input by optimizing the component geometry

- Selection of the ideal material (by using an expensive material a minimized wall thickness, cycle time etc. can be achieved due to the higher levels of durability)

- Consideration of the cooling phase/cycle time of a material (identification of the material with the shortest cycle time)

- Selection of the ideal injection moulding machine (clamp force size)

- Reduction of the warpage problems

- Selection of the most economic surface decoration (painting, two shot moulds, film)

Plastics simulation center calculates the differing component and implementation variants

The simulation of the injection moulding process, the calculation of the components under load and the lifetime prediction or also a tolerance analysis enable developers to already identify the appropriate component and implementation variants in the development phase and to achieve the optimum cost in keeping with the additional given constraints.

As a specialist for the simulation of injection moulding processes and component stresses Impetus Plastics Engineering has so far demonstrated its expertise in hundreds of projects. The calculation of component variants, FEM simulations of load conditions, deformation situations and failure modes, structural analyses of glass fibre reinforced injection moulded parts as well as anisotropy tests can be found in the service portfolio.