Simulation programs forecast accuracy

We precisely know the limit

The simulation of injection moulding processes has become a vitally important standard tool in the development of injection moulded parts. However the calculations that the models are based on still require compromises in a number of cases - especially if complex geometries are at hand. The results of each simulation calculation must therefore be interpreted based on the capabilities of the individual simulation programs.

Constant comparison of various simulation programs

We constantly test the different simulation programs in our plastics simulation center with regard to the most diverse criteria and are therefore able to draw conclusions regarding the precision of the calculated results. In addition we derive advantage from a cooperative arrangement with the Rosenheim University of Applied Science to determine the limits of the simulation techniques very precisely in systematic field tests and determine the actual material coefficients relevant to the simulation.

Further development of the calculation options for fibre-reinforced components

In this way the calculation options of complex, fibre-reinforced components are comprehensively evaluated based ion in-house fundamental tests in the course of the research work in the simulation center of Impetus Plastics Engineering.

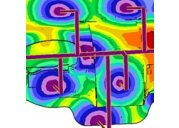

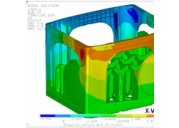

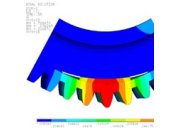

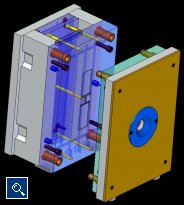

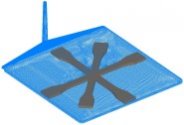

To calculate the fibre orientation, the resulting warpage and the location-dependent rigidity of the component the option of "mapping" (transferring the properties from one net to the other) as well as the direct rheological and structural mechanical calculation based on one and the same volume net are given. The fibre orientation determined by the 3D filling simulation can be used without any interface by the ANSYS FE program for the mechanical design.

The results help our customers to further extend the application options of numerical calculation methods and to continuously improve the precise design of complex, fibre-reinforced components which continue being a challenge due to the anisotropic component behavior.

As a specialist for the simulation of injection moulding processes and component stresses Impetus Plastics Engineering has so far demonstrated its expertise in hundreds of projects. The calculation of component variants, FEM simulations of load conditions, deformation situations and failure modes, structural analyses of glass fibre reinforced injection moulded parts as well as anisotropy tests can be found in the service portfolio.

Comparison of simulation and actual practice during the anisotropic component designs with the 3D filling simulation MOLDEX and the ANSYS FE program during different calculation procedures.

Comparison of simulation and actual practice during the anisotropic component designs with the 3D filling simulation MOLDEX and the ANSYS FE program during different calculation procedures.